ProcessPro and Hydranautics are confirmed sales partners in Baltic countries and Eastern Europe region.

Hydranautics is one of the global leaders in membrane technology with range of the most advanced, high-performance membrane products for all applications and industries.

Product applications include potable water, boiler feedwater, industrial process water, wastewater treatment, surface water treatment, seawater desalination, residential water, electronic rinse water, agricultural irrigation and pharmaceuticals.

Hydranautics products are made to reach highest quality level of technical excellence and product quality. Widely developed manufacturing sites located in Oceanside – USA, Shiga – Japan and Shanghai – China.

Hydranautics product range covers the main industries and segments like:

- Chemical Processing Industries

- Dairy

- Industrial

- Microelectronics

- Mining

- Municipal

- Oil & Gas

- Pharmaceutical

- Power Generation

- Residential

Common partnership confirmed by certificate as ensure us to act as a part of well-known product brand as technical trader and help us to provide clients best product in membrane technologies with producer’s technical support directly.

Within several years of tight cooperation in region, were served and delivered numerous of valued projects with high quality RO membranes Hydranautics.

We are proud to say that no claims for quality and service were not get in back and ready to serve clients on the same way in future.

Moments from activity with Hydranautics

Due to tight cooperation with Hydranautics directly, we able to avoid any extra expenses on stocking or reloading. Each your order served directly from producers stock case-to-case.

With long term clients we keep local stock according agreed terms of collection and save them extra expenses and staff time for planning, stocking, logistic and etc.

Being a direct partner Process Pro ensure prompt and qualified technical support based on long time producers experience, local or client oriented stock locations as ensure us to react to clients demands within short time and other features.

Folllowing to producers experience time to time we held trainings for our clients and customers in order to present latest innovation of producers, solve special clients demands or find common project solution.

Together we started to develop number of special product product applications in region clients facilities and hoe to get satisfied with results in near future.

Even if you are OEM, industrial user , service company or trader-we are your choice. We serve all segments and all clients – we are the right partner for every company as operates in industrial sector.

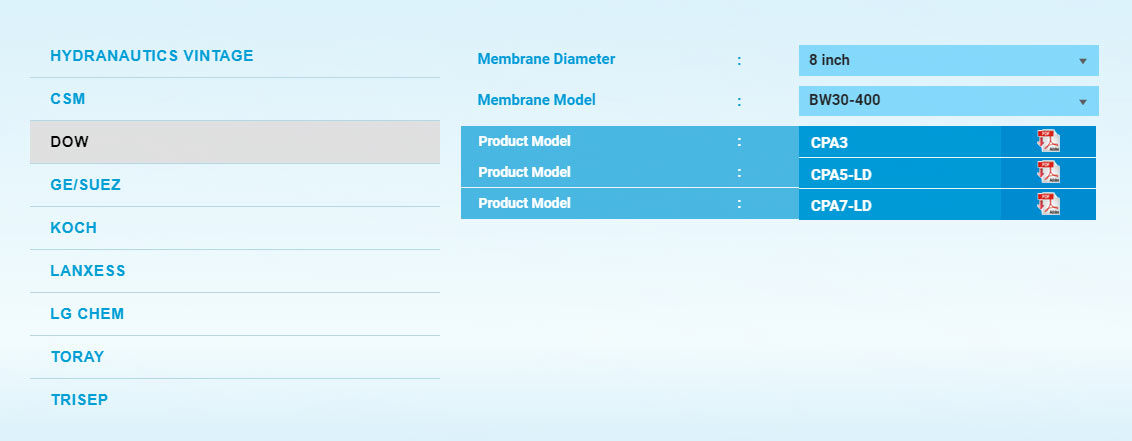

Hydranautics Cross-Reference

New very useful tool for Hydranautics clients now available online-save you time, energy an costs and get solution to compare membrane models from other manufacturers alongside Hydranautics membranes, and finding out which Hydranautics membranes closely match your requirements!

Please use new convenient option – comparing and choosing right with our Cross-Reference Tool.

To use this tool, you need to select the competitor brand, the required membrane diameter and the model number. The tool then guides you with the recommended Hydranautics membrane model(s) and its specification sheet suiting your requirements. Alternatively, you can go to the membrane family webpage on clicking the specific Hydranautics product model.

Please note that this tool may not be an exact one-for-one match, but surely does offer you a membrane selection closest to your requirements.

Explore to experience this tool innovation.

We offer complete package range of Hydranautics reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF) and microfiltration (MF) membrane-based solutions to the water and separations industries.

Below is overview of the core Hydranautics products range across all sectors of industry as provide Process Pro :

REVERSE OSMOSIS MEMBRANES HYDRANAUTICS

SWC (Sea water composite) line

We offer range of Hydranautics SWC RO membranes to meet the demands of desalination industry. SWC membranes have improved the productivity and salt rejection for more than two decades while reducing their environmental impact.

SWC membranes come in a range of innovative formulations depending on the level of seawater salinity required and suitable for varying degrees of seawater salinity. Each type of SWC elements offers the highest productivity and salt rejection rates in the industry combined with the optimized flow, low fouling and low energy consumption.

Available series: SWC4, SWC5, SWC6

CPA -High rejection membranes (Composite poliamide) line

Spiral-wound RO membranes are available in a variety of sizes and ensure performance with the highest salt rejection rates for brackish water applications. High efficiency and cost-effectiveness make CPA series membranes as one of the best high-rejection brackish water RO membranes in the industry.

Because of its exceptionally high salt rejection, CPA membranes are widely used in power generation, pharmaceutical, electronics and semiconductor industry.

Available series: CPA2, CPA3, CPA5, CPA6, CPA7, CPAE

ESPA Low energy High rejection membranes (Energy Saving polyamide) line

ESPA membranes are the choice for applications where demanding high-energy efficiency, with uncompromised productivity and salt rejection. Operates at lower pressures, ESPA elements produce high quality water in a range of water treatment applications, ensuring energy cost savings.

ESPA membranes are used in the treatment of drinking water, industrial process waters, municipal and industrial waste water recovery and reuse because of this exception performance capability. These membranes also serve as part of polishing units in seawater desalination plants when boron rejection is critical.

Available series: ESPA1, ESPA2, ESPA4

Sizes: 4040, 8040

LFC Low fouling membranes (Low fouling composite) line

LFC3-LD -innovative low fouling membranes. LFC3-LD provides significant reduction in fouling rates increasing the membrane’s efficiency by restoring nominal performance after cleaning.

With the low fouling LD Technology™, the differential pressure gets reduced lowering the biological and colloidal fouling inside the membrane, and successfully reducing the number of cleanings required.

LFC3-LD membrane is available in diameters of 4.0 and 8.0 inches.

RO mini elements

Available series : ESPA, SWC.

ULTRAFILTRATION MEMBRANE SOLUTIONS HYDRANAUTICS

Ultrafiltration elements HydraCAP, HydraCAP MAX

HYDRAcap UF elements are used to treat surface water, ground water, seawater, and waste water as either primary treatment or as pre-treatment to reverse osmosis (RO) and Nano filtration (NF). Compared to conventional pretreatment, HYDRAcap allows higher fluxes for RO and NF systems while maintaining longer intervals between cleanings. In some cases it replaces conventional pretreatment for portable applications, ground water recharging and water recycling.

HYDRAcap enhances RO and NF element system design and operating conditions when used as a pre-treatment step for desalination, treatment of surface waters and municipal and industrial effluents.

Types: HydraCap40, HydraCap60, HydracapMAX40, HydraCApMAX 60, Hydracap MAX 80

HydraCap serie

Modules are suitable for a wide range of applications including ground water and pretreated surface water for potable water production. The element structure enables to operate at high fluxes for long filtration periods.

All HYDRAcap® models meet these following certifications for potable water applications: NSF61, ACS (France), DWI (UK).

Available series: HYDRAcap40, HYDRAcap40-LD, Hydracap 60, HYDRAcap 60 LD, HYDRAcap 60+

Hydracap Max ultrafiltration serie

HYDRAcap® MAX is a technology using ultrafiltration PVDF TIPS hollow fibers (0.08 micron pore size). The pressurized hollow fiber modules are suitable for a wide range of applications as either final treatment or as pretreatment to reverse osmosis (RO) and nanofiltration (NF).

- Industrial or municipal waste water

- Sea water

- Surface water and ground water

Available series: Hydra cap Max 40, Hydracap MAX 60, Hydracap MAX 80

HydraSub serie

Hydranautics offers submerged modules with PVDF hollow fiber for MBR applications.

Two types of technologies are available:

- HYDRAsub® technology uses a microfiltration fiber with a pore size of 0.4 µm. Modules size proposed are ranging from 15 to 1500 m2

- HYDRAsub®MAX technology uses an ultrafiltration fiber with a pore size of 0.05 µm. Modules size proposed are ranging from 40 to 2400 m2

For detailed information please contact us.

NANOFILTRATION (NF) ENERGY SAVING MEMBRANES HYDRANAUTICS

These membranes are ideal for applications requiring the removal of divalent ions, organics, color, bacteria and viruses.

Available series: ESNA serie, Nano BW, NANO SW, Hydra Core series.

PROCESS MEMBRANE SOLUTIONS HYDRANAUTICS

Process Separation product range includes reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF) as well as microfiltration (MF) membranes used in various special liquid-liquid separation applications other than waste water treatment and desalination.

DairyRO products is widely used in concentration of UF permeate, whey, skim milk and polishing applications.

Main series:

- Dairy reverse osmosis membranes, serie DAIRYRO

- Dairy Nanofitration membranes, serie DAIRYNF

- Dairy ultrafiltration membranes, serie DAIRYUF

- Hydra CoRe membranes

- SanRO membranes

- SupRo membranes

- Hydrapolish membranes

General packing information

Packing details:

- 8 inch elements-25 psc per crate

- 4 inch elements-81 pieces per crate

- mini elements-25 peces per box

Ultrafiltration modules:

- Hydracap products-8 peces per crate

- Hydracap MAx-6 pueces per crate

* this information for full crate deliveries only. We supply exact quantity of elements as per client needs accordingly.

Key features to use Hydranautics in your projects:

- Well known brand and wide range of applications

- Internationally certified product for major applications

- Stable quality for proven producer.

- Comprehensive range of all products and applications and full technical support under your case

- Prompt delivery from client oriented stocks

Benefits to cooperate with Process PRO for you:

- Receive tailored solutions with Hydranautics for membrane technologies and applications according your case.

- For traders: Expand your product range and receive industry-leading technical support.

- Looking not for elements but for whole water treatment system include Hydranautics? We are ready to serve clients with whole solution based on Hydranautics technologies. Process Pro will provide you full technical service from the inquiry up to system delivery according your case.

- Remove the multitude expenses and troubles of storage and delivery of products- get the product when you need it only.

- Save your budget, staff and time for planning and delivery process. It’s enough to contact us and we will propose you full process from the beginning up to delivery of products on requested dates.